Home » Products » NGV Refueling Systems » Gas Regulating And Treating Equipment »Gas Desulphurization Tower

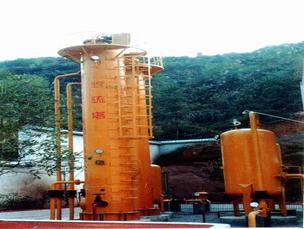

Gas Desulphurization Tower

Gas Desulphurization Tower

1. It adopts the specialized and high-efficiency desulfurizer to achieving the purpose of desulfurating purification to the raw natural gas. The sulphur content of the high-purity natural gas is below 6m/Nm3 after processing, which does contribution to avoiding H2S doing stress corrosion to the station equipments and H2S’ recontaminating of vehicles’ exhaust emission.

2. To achieve the continuity of desulfuration purification, the choosing of different operation modes of single tower or twin tower, series or parallel is according to the condition of gas- quantity and gas-quality disposal. Desulfurizer has the capacity of repeated adsorption and regeneration and it is featured by long service time and changing cycle length.

Desulfuration System

Main Specification of Desulfuration Tower:

| 1 | Type | DN800~DN1400 |

| 2 | Max. Working Temperature (℃) | 60 |

| 3 | Regeneration Temperature (℃) | ≤60 |

| 4 | Working Pressure (Mpa) | 0.3~1.6 |

| 5 | Capacity (Nm3/h) | 1000~3000 |

| 6 | H2S Content (In / Out) (mg/Nm3) | 3000~≤6 |

| 7 | Desulfuration Agent | CT8-6B Special |

| 8 | Volume (m3) | 3.0~12.0 |

| 9 | Structure | Vertical |

| 10 | Adsorbing & Regenerating Cycle (days) | 80 |

| 11 | Fixing mode | Outdoor & fixed |